1、主機Basic Machine:

l DAISY系列測量機采用國際先進的有限元分析設計方法�����,使其具有機械結構剛性強�����、幾何誤差小,具有高精度�����、高性能和高穩(wěn)定性的優(yōu)點��。

Adoption of advanced F.E.M. (finite element method) makes it have a strong rigidity, small geometry error, high precision, high performance and high stability.

l 機械整體結構采用剛性結構好�、質量輕的全封閉框架移動橋式結構。其結構簡單�����、緊湊�����、承載能力大��、運動性能好��。

The mechanical overall structure adopts strong rigidity, light weight and close frame movable bridge structure, which is simple, compact and has strong loaded capacity and good moving performance

l 固定優(yōu)質花崗巖工作臺��,使其具有承載能力強�、裝卸空間寬闊、便捷��。

Granite fixed workable ensures strong heavy load, expanse and simplicity for assembly and unassembly.

l Y向導軌采用燕尾式,定位精度高�����,穩(wěn)定性能好���。

Y axis guideway adopts dove tail type, which has high precision and good stability.

l 三軸采用優(yōu)質花崗巖�,熱膨脹系數小�����,三軸具有相同的溫度特性�,因而具有良好的溫度穩(wěn)定性、抗實效變形能力����,剛性好、動態(tài)幾何誤差變形小�。

Three axis’s adoption of quality granite guarantees small coefficient in thermal expansion and uniform temperature specialty so that it serves to excellent stability in temperature, good anti-transmogrification, strong rigidity and small geometrical error in motion.

l 三軸均采用自潔式預載荷高精度空氣軸承組成的靜壓氣浮式導軌���,軸承跨距大�,抗角擺能力強��,阻力小、無磨損����、運動更平穩(wěn)。

Three axis’s adoption of quiescent air pressure air-bearing guide way, comprised of air bearings which are self-cleaning, pre-loading and high precision, guarantees the large span of bearings, strong anti-sways, small resistance, no abrasion and stable motion

l 橫梁采用精密斜梁設計技術(已獲專利)���,重量輕����、重心低���、剛性強��,動態(tài)誤差小�����,確保了機器的穩(wěn)定��。

Crossbeam’s adoption of precise designing technology of inclined girder (patent) guarantees the machine’s lightweight, low center of gravity, strong rigidity and small error in motion so that the stability of the machine is strengthened.

l 采用國外進口反射式金屬帶狀光柵計量系統(tǒng)�,與大多數工件具有相近的熱膨脹系數���,確保了良好的重復精度�����。

Adoption of world famous reflecting metal tape measuring scale system, which has a close thermal expansion coefficient with most work piece and assure a good repeatability.

l 驅動系統(tǒng)采用國際知名品牌的高性能直流伺服電機��、齒形帶傳動裝置�,確保傳動更快捷、更精準���、運動性能更佳����。

Drive system adopts world famous high performance DC servo drive system and dentiform tape gearing, which guarantee the drive’s fastness, precision and perfect movement.

l Z軸采用氣缸平衡裝置����,極大的提高了Z軸的定位精度及穩(wěn)定性。

Z-axis adopts cylinder equilibrator system, which improves orientation precision and stability greatly for Z axis.

l 控制系統(tǒng)采用德國知名的SB專用三坐標數控系統(tǒng)���,具有國際先進的上下位機式的雙計算機系統(tǒng)���,從而極大地提高系統(tǒng)的可靠性和抗干擾能力,降低了維護成本�。

The control system’s adoption of the exclusive SB system with high integration from Germany strengthens the system’s capability, reliability and anti-jamming performance by a large extent.

l 軟件采用具有獨立知識產權的、功能強大的AC-DMIS測量軟件包�����,其完善的測量功能和聯(lián)機功能�,為用戶提供了完美的測量解決方案。

Software adopts self-owned intellectual property and strong function AC-DMS software. With its perfect measuring and online function, it will meet customer’s challenging demand with a comprehensive measurement solution.

2����、技術指標Technical Index:

01:測頭系統(tǒng)/ Probe System:

RENISHAW MH20i手動雙旋轉可分度測頭系統(tǒng)manual double-rotary probe system

技術參數Technique parameter:

測頭部分probe TP20測力模塊一個include one TP20 force module

感應方向Sense direction ±X ±Y ﹢Z

測頭座分度機構Total angular movement:

繞 A軸A axis(水平軸) 范圍 0°~90°最小步距15° 0° to 90° in 15° steps

繞B軸B axis(鉛垂軸) 范圍±180°最小步距15° 0° to ±180° in 15° steps

空間位置Total number of positions 168個

重量Weight 210g

02:測針組RENISHAW Stylus Kit(mm):

測針(mm):

訂貨號 | 型號 | 材料 | 測球直徑 | 長度 | 桿直徑 | 有效長度 | 數量 |

A-5003-0033 | PS48R | 紅寶石測球/碳化鎢桿 | 1 | 20 | 0.8 | 12.5 | 1 |

A-5000-3603 | PS2R | 紅寶石測球/不銹鋼桿 | 2 | 20 | 1.4 | 14 | 1 |

A-5000-4160 | PS16R | 紅寶石測球/不銹鋼桿 | 3 | 20 | 1.5 | 17.5 | 1 |

A-5000-7807 | PS8R | 紅寶石測球/不銹鋼桿 | 2 | 10 | 1 | 6 | 4 |

A-5000-3609 | ―― | 紅寶石測球/不銹鋼桿 | 2 | 16.5 | 1.4 | 12 | 1 |

測針加長桿(mm):

訂貨號 | 型號 | 材料 | 直徑 | 長度 | 數量 |

M-5000-3648 | SE5 | 不銹鋼桿 | 3 | 20 | 1 |

測針中心座:

訂貨號 | 型號 | 材料 | 中心尺寸 | 有效長度 | 數量(個) |

A-5000-3627 | SC2 | 不銹鋼桿 | 7 | 7.5 | 1 |

03:校準器Datum Tool:標準球Datum BallΦ25及萬向球座Kit T5 1套/set

04:性能指標Performance Data:長度計量系統(tǒng)Length Measuring System:英國RENISHAW反射式金屬帶狀光柵尺/reflection metal-tape grating scale.

分辨率Resolution: 0.5mm;

測量范圍Measuring Range X×Y×Z: 500mm×600mm×400mm

示值誤差Measuring Erro: MPEE≤2.2+L/300mm

探測誤差Probing Error: MPEP≤2.2mm

3�、環(huán)境要求Environment Requirement

01:溫 度Temperature:20+2℃ 1℃/h 1℃/m 2℃/24h

02:濕 度Humidity: 40%-70%

03:電 源Power Supply:220V+10%, 50HZ-60HZ

04:氣 源Air Supply:≥0.55MPa

4、控制系統(tǒng)Control System:德國SB公司CNC系列三坐標測量機專用控制系統(tǒng)

Well known CNC series SB controller system for CMM.

———德國先進技術和中國理念的完美結合

International famous CMM controller system

———性能卓越�、超強的抗干擾能力

Excellent functionality and super powerful anti-interference capability

l 德國知名三坐標測量機專用控制系統(tǒng)

German well-known SB control system for CMM

l 采用國際先進的上、下位機式的雙計算機控制系統(tǒng)

Internationally advanced up-down dual computers control system

l 支持多種測頭系統(tǒng):觸發(fā)測頭�、掃描測頭、光學CCD測頭�、激光測量系統(tǒng)

Support of multiple probe systems: touch-trigger probe, scanning probe, optical CCD probe, laser measuring system.

l 內置控制技術軟件,可實現四軸伺服驅動及運動狀態(tài)優(yōu)化調整

Software of Built-in control technology to realize the servo drive for 4 axis and optimal regulation of motional status and adjustment of servo parameter to make automatic optimization

l 支持RENISHAW全系列測頭連接系統(tǒng)PICS

RENISHAW probe controller embedded to support the full series connected with PICS.

l 內含智能掃描控制系統(tǒng)���?����?蓪崿F空間輪廓曲線���、曲面自動掃描控制

Intelligent scanning control system embedded to achieve the automatic scanning control of spatial contour curve/surface

l 內部采用先進的連續(xù)運動軌跡插補算法��,可進行測量軌跡的優(yōu)化整合���,自動生成合理的測量運動軌跡

Adoption of advanced interpolation algorithms for continuous motion track to optimize the measuring track and automatically generate logical measuring motion track

l 采用多種控制模式,提供多種安全保障功能

Multiple control modes to provide multiple safety functionality

l 具有故障自診斷糾錯功能

The functional self-diagnosis and self-correction for malfunction

l 具有內部溫度監(jiān)控系統(tǒng)

Monitoring system of interior temperature

l 內部通訊采用多種接口標準�����,便于計算機聯(lián)網升級

Multiple interface standards for intercommunication to ease computer’s network and upgrade.

l 配置專業(yè)化的三軸聯(lián)動操縱桿及按鍵面板的操縱盒

Specialized three-axis-linked joystick and the operation box with button panel

l 輸入��、輸出���、光隔離具有良好的電氣可靠性��、穩(wěn)定性�����、安全性及超強的抗電磁干擾能力����,符合歐洲電氣安全標準

Favorable electrical reliability, stability, security and super powerful capability of anti-interference and against electromagnetism in conformity with European EC standard.

5��、計算機系統(tǒng)Computer System

01:DELL計算機Computer :

CPU:雙核Dual core 2.5G

操作系統(tǒng)Operating System:Windows XP +SP2

內 存Memory:1G

硬 盤Hard disc:320G

顯 卡Video Card:TNT/GERFORCE

顯卡驅動推薦使用以下版本The drive of Video card recommended: WINXP VERSION 30.82

圖形庫Graphic Base:OPENGL(操作系統(tǒng)提供Provided by Operating System)

顯示器Display: 19″液晶顯示器LCD display

02:打印機 Printe: HP A4彩色噴墨/Color inkjet

03:氣路連接件Pneumatic connecting parts

管接頭Cable connector SPCF-10-02+SBT-10-02 1套/set

緊固膠管用卡箍Clipper φ16~φ25 1套/set

氣管Air cable φ10 1.5m

6、軟件系統(tǒng)Software System:AC-DMIS EXT測量軟件包/Measuring Software package :

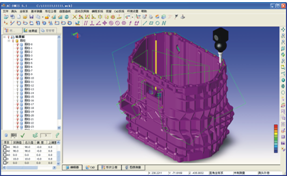

AC-DMIS 是AEH測量設備股份有限公司開發(fā)的新一代通用三維測量軟件包�����。以通過PTB認證的嚴謹算法為核心�,以體現當今國際上專業(yè)三維建模���、數字模擬及CAD/CAM軟件開發(fā)最先進理念的高效�、穩(wěn)定的開發(fā)平臺為基礎��,融合AEH測量設備股份有限公司的創(chuàng)新精神和在坐標測量領域的豐富經驗�,AC-DMIS 通過其簡便易用的操作界面、豐富完善的功能�、無限的可擴充性及ISO標準的公差評判為各界各種各樣的幾何量測量問題提供了有效、便捷�����、完美的解決方案���。幾千家的客戶群就是AC-DMIS強大測量功能軟件成功的見證者�。

AC-DMIS, the new powerful generation of universal 3D measurement software researched by Xi’an high-tech industrial metrology CO.,Ltd. Its core precise arithmetic is fully certified by PTB certification, the software’s researched platform is from the most advanced, professional 3D model making, digital simulation CAD/CAM software and combines AEH innovation sprite and abundance experiences of CMM field, Friendly, simple and convenience user interface, perfect functions, unlimited extension ability and ISO tolerance evaluation standard offers fast, accuracy, effective, high-efficiency solution for all kinds metrology measurement requirements. Thousands of customer group are the best witness to demonstrate the success of comprehensive AC-DMIS.

AC-DMIS.EXT的功能main feature:

l 支持多種控制系統(tǒng)如����,UCC���、PANTEC、SB等��;

Support for multi-controller systems, UCC, PANTEC, SB etc;

l 支持多種測頭���,如:觸發(fā)式�、連續(xù)掃描式��、影像式和線激光等�,方便進行多種形式的測量;

Probe system, trigger mode, continuous scanning mode, image mode and laser scan, etc, to satisfy all measurement requirements;

l 模塊化的軟件結構��,具有無限的加掛各種專用軟件(齒輪���、葉片�����、凸輪����、蝸輪蝸桿等)及進行二次開發(fā)的可能;

Modularized software structure with the capability to add special software (gear, vane, cam, warm/wheel etc.) and secondary development.

l 具有簡潔直觀的操作界面及可追溯的清晰的操作流程記錄����;

With brief operation interface and traceability legible operation process track record;

l 具有點、線�����、面���、圓、圓柱�、圓錐、橢圓����、圓槽、方槽����、圓環(huán)、球�����、曲線等多種基本幾何元素的測量及評定;

Geometric measurement and evaluation: point, line, plane, circle, cylinder, cone, ellipse, round slot, rectangle, torus, sphere, curve and surface, etc;

l 通過對元素的構造��、轉換���、再現�、投影���、存儲/調用及相關計算����,可實現對已測元素進行后續(xù)操作�����,得到設備不同狀態(tài)的轉換結果����、角度、距離等�;

Element construction, transform, reappear, projection, store, recall and relation calculation to realize following operation of measured elements and obtain result, angle, distance, etc, under different machine status;

l 強大的形位公差測量功能涵蓋了所有的相關內容及評定方式,測量內容包括直線度�����、平面度、圓度��、圓柱度�、輪廓度、垂直度����、平行度、傾斜度�����、同軸度���、同心度、對稱度�、位置度、跳動誤差測量��、徑向圓跳動�����、徑向全跳動�����、端面圓跳動、端面全跳動����;公差規(guī)則包括獨立原則和相關原則等;

Powerful GD&T function includes all relative content and its evaluation items, Straightness, Flatness, Roundness, Cylinder form, profile form, perpendicularity, Parallelism, Angularity, Coaxiality, Concentricity, Symmetry, Position, Axial runout, Radial runout, Total axial runout, Total radial runout; tolerance regulation includes RFS, LMC,MMC, etc.

l 不同工件坐標系的建立方式可滿足各種工件的測量和評定�,有適合于箱體類零件的工件位置找正,有適合于復雜曲面類的RPS找正�����,也有適合于模具檢具類的三個中心點找正及曲面321找正等���;

Multi-coordinates system alignment methods satisfy required measurement and evaluation for different parts, “part coord-sys” mode is used for shaped box part alignment; “RPS alignment” mode is mainly for complex surface part alignment, and “3 center point alignment” and “surface 321 alignment” modes are suitable for model part alignment;

l 支持多語言的隨意切換���,公、英制的選擇����,極、直坐標系下測量的選擇等����;

Support for instant switch of multi-language, length unit(mm, inch); coordinate system (Cartesian or polar) etc;

l 具備清晰的樹形程序編輯器和方便快捷的字符式程序編輯器���,通過智能化的自學習測量,即使不懂編程亦能應用自如��;

Intellectual self-study program: with clear tree editor and convenient character editor, even new learner will feel like using with it;

l 簡捷直觀的測量路徑顯示功能�����,以便判斷運動軌跡是否安全合理����,測量過程是否干涉;

Visible measuring path display: for safety and anti-collision prediction before starting measurement;

l 可實現手動測量與參數化的特征測量之間的無縫切換�����;

Instant switch between manual measurement and CAD feature auto measurement;

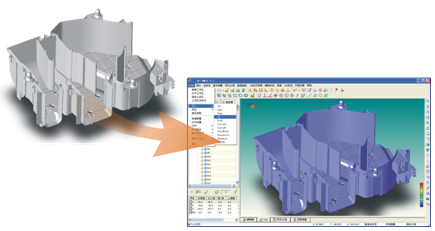

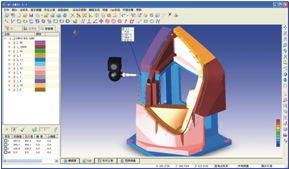

l 具有CAD三維模型(SAT��、IGES�、STEP)的導入與轉換功能��;可用鼠標直接在模型上拾取基本幾何元素��、線曲面等元素,自動生成程序并完成特征測量��;

3D CAD model (SAT����、IGES、STEP) import and transform; use mouse to pick geometric element, curve, surface, etc. from model directly, and create measuring program and complete feature measurement automatically;

l 基于三維模型的脫機編程���、模擬測量和同步測量的實現�����,使編程更加直觀���;

Offline programming, simulation measurement and synchro measurement which based on 3D model, makes programming more intuitional; (Ext,Std);

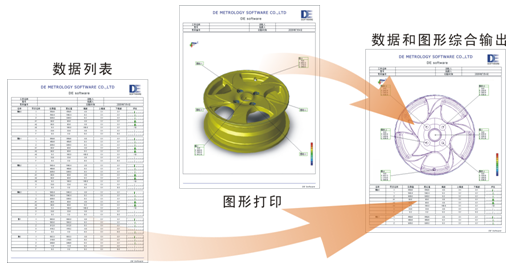

l 具備多種輸出格式,如:word���、excel(Microsoft office或Open office)����、bmp���、pdf��、iges�����、step���、dat����、文本文件���;

Multi-output formats: word, excel (Microsoft office或Open office), bmp. Pdf, igs, step dat and text document;

l 提供客戶自定義樣式的報告���,方便客戶對測量結果進行統(tǒng)一管理;

Support customized report format, satisfy customer special needs and convenient customer for result’s management;

02:服務承諾For Service Quality:

l 如我公司接到用戶設備故障請求服務電話����,在2小時內予以響應,如有必要在24小時內派技術人員赴現場解決問題�。

If we get telephone request services about equipment failure from users, we will response to the request in 8 hours, if necessary we will send technical engineer to the customer’s site to solve problems within 24 hours.